Choose timber

You probably think there only two types of wood; hardwood and softwood.

Hardwood is long lasting, has a beautiful grain and the most strength but it is expensive and difficult to find an ethically sourced supply. Softwood is cheaper and sustainably sourced but less resistant to rot and not as strong so it does not last as long and normally needs chemical treatments and regular maintenance.

There are other options though. There are a range of modified woods that use softwoods as their raw material and, via various processes, treat this timber so it gains some or all of the superior properties of hardwoods.

Selection of hard and soft woods

So before you order your timber think about the woods use; will it be seen, does it need to withstand exterior weather conditions does it need a certain strength for a particular structural use and does it need to have a minimum life in use? Once you know what you need the timber to do you can choose the best option within your price range.

Further Reading

- Wikipedia Hardwood and Softwood

- Comparing hardwoods and softwoods

- Softwood – material characteristics

- Hardwood – material characteristics

Terminology

When you research and buy your timber you will come across certain terms. This information is available on the internet for each species of wood and each brand of modified wood. Here is a quick guide to the important ones.

- Dimensional Stability. This measures the amount wood changes in shape usually due to absorbing water in wet conditions and then loosing it again when it is dry. If dimensional stability os low the wood will expand and contract changing shape a lot. This results in warping - overtime the wood bends. In addition it can weaken joins and fixings. If you are using timber for applications where a tight fit is important – doors, windows, cladding etc – then you need a wood with a high dimensional stability.

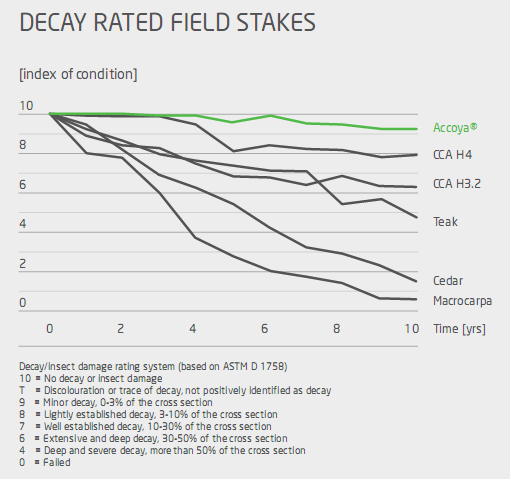

- Decay. Wood rots over time and this is increased in exterior environments and when wood is in contact with the ground. A fairly standard test of the susceptibility of wood to decay is the field stakes method – wood stakes of the same size and shape are embedded into the ground and then left. A few years later they are dug up and the degree of rotting compared, see the chart below for an example of the results. Some treatment methods can confer extreme rot resistance which have meant Aluminium can now be replaced by beautiful wood in lots of different external applications, greenhouses & coldframes.

Different decay rates for types of wood

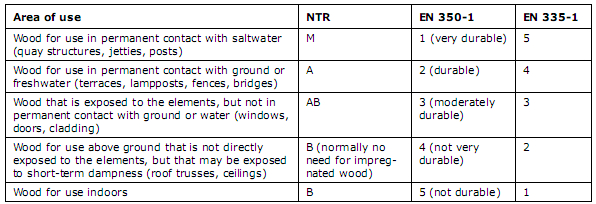

- Durability. This reflects the woods expected life span and it differs between interior, external and water contact applications. In ground contact and salt r fresh water contact are also additional criterion. Each species of wood has an expected life for each of these applications. All major treatment processes should also have a published expected life for each of these applications which should be backed up by independent studies. Heat treated wood is not usually suitable for in-ground contact or water contact applications. The table below compares some of the durability standards that you might see.

How wood gradings relate to applications

Pressure Treatment / Tanalising

This process involved putting the timber in large vessels with various chemical compounds. The vessels internal pressure is raised to force the chemicals into the wood to ensure it is fully impregnated. It is the chemicals used that determine how the wood changes and these can vary depending on the manufacturer.

Traditionally the chemical mix used was CCA (chromated copper arsenate) however it’s use has been replaced in much of the developed world due to concerns over the use of arsenic and chromium compounds. These compounds are highly toxic and caused pollution when they were produced and the wood rotted. There were also concerns that leaching of these compounds from the wood while in use could damage the health of people in buildings containing the wood or eating food grown around this wood. In Europe you are not allowed to use it for residential buildings. However there are now alternatives that are considered to be safe.

Modern alternatives are;

- ACQ is short for Alkaline copper quaternary. This treatment uses an insecticide, fungicide and ammonium compound and a cooper preservative. This is a relatively new chemical mix for this process which has won environmental accolades for greatly reducing the use of arsenic and chromium compounds.

- Cooper Azole is similar to ACQ but it uses a slightly different chemical mix that should make it safe around food crops. Brands like Tanalith and Wolmanized use this process.

- Copper Naphthenate is a good alternative to creosote. It preserves wood and prevents it absorbing too much water it has also been shown (at specific concentrations) to prevent termite attack. As a result it is used as treatment for exterior uses like fences and beehives.

Copper treated wood can corrode steel so you need to use double galvanised screws and brackets if you use copper treated wood.

Pressure treatment chemical process

No Chemical Alternatives?

Public trust in pressure & chemical treated woods is low due to their association with CCA. The general public does not understand that there are different treatment methods and that modern alternatives are more rigorously tested, don’t leach much and don’t use toxic compounds even if they do leach. However even understanding all this many of us would still feel uneasy about using a material that was soaked in so many metallic compounds especially if we wanted to use the timber in a garden setting where we grow fruit or vegetables.

There are another branch of alternative treatments that either don use metallic compounds at all but have the same or better outcomes for wood durability and dimensional stability.

- Acetylation. This sounds quite chemical but it essentially is pickled wood! An industrial form of vinegar (acetic anhydride) is used to change the chemical structure of the wood. The only residual chemical from the process is vinegar so it is an environmentally friendly production process. It changes the chemical structure of the wood itself rather than filling it with a mixture of insecticides and pesticides. The woods free hydroxyls are altered so they don’t react with water. This does three things; firstly the wood does not absorb water so it does not swell and contract when in contact with water. This gives the wood excellent dimensional stability meaning it doesn’t warp and fixings last longer. Secondly free hydroxyls seem to be important to wood rotting – remove the free hydroxlys and the wood doesn’t rot. This also seems to make the wood indigestible to insects including termites. The finished product the strength and durability of the best hardwoods so why isn’t everyone using it. It turned out to be very hard to produce this wood in a cost effective way and a successful process has only recently been designed. It is now manufactured by Accoya and distributed throughout Europe and the USA, you can find out more about the wood treatment process on their website.

The wood 'Acetylation' process

- Thermal Treatment. The wood is baked in a dry vessel. This process also changes the chemical structure of the wood to make it less prone to decay and insect attack. The baking changes the colour of the wood and it is an attractive coffee coloured however most of these processes also weakens the wood (it is about 20% weaker than the untreated pine) making it unsuitable for some applications. Some manufactures have developed more complex processes of heat treatment that retain most of the woods strength however the more complex process is reflected in their price.

Further Reading

- Understanding decay resistance, dimensional stability and strength changes in heat-treated and acetylated wood

- UK Timber Cladding Association

- American Wood Protection Association

- LEED

Self Build Blog

Self Build Blog